Organisational Process Safety

Enhanced safety with a new approach to Risk-Based Process Safety (RBPS)

High hazard industries have long invested in process safety management systems, and, as consumers and the public increasingly scrutinise the safety practices of companies of all sorts and sizes, interest in Process Safety (PS) has grown.

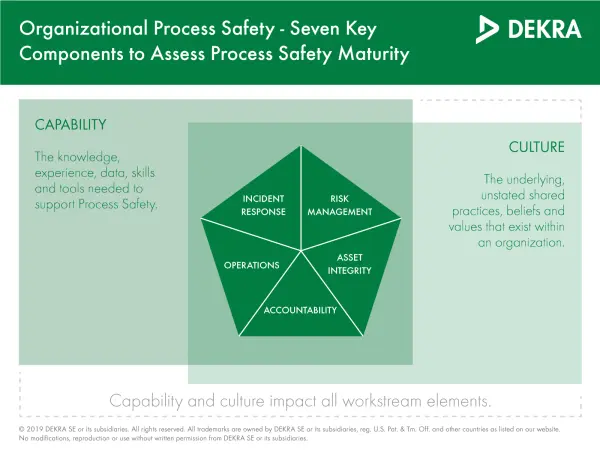

However, conventional PS, often compliance-oriented and dictated by regulatory bodies such as OSHA in the US or directives like Seveso in the UK, has not prevented disasters from happening. It is clear that traditional audits, while appropriate for evaluating a program against a given standard, fail to address organisations’ capability and culture, both of which substantially impact process safety outcomes.

Organisational Process Safety (OPS) is our answer to the call for innovative solutions to persistent process safety challenges. Drawing on decades of experience with partners in the oil and gas, pharmaceutical and chemical sectors, our experts have designed a ground-breaking approach to risk-based process safety that incorporates organisational culture and capability as well as human factors, based on the CCPS (Center for Chemical Process Safety) risk-based process safety model. Our OPS tool examines the critical areas identified by the CCPS, generating repeatable and reproducible results, customised recommendations and plans for improvement. Applicable to any industry striving for safety excellence, OPS not only addresses compliance, it goes beyond what existing process safety systems can offer to bring industries closer to zero harm.

Your Benefits

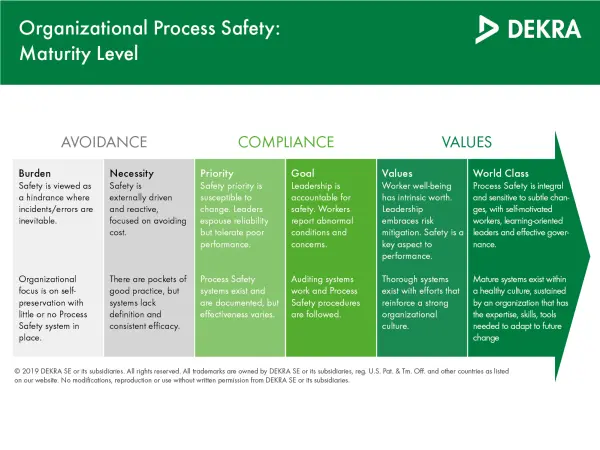

- An objective, precise, repeatable and reproducible measure of the maturity level of your site or organisation.

- Optimal interventions to improve your organisation’s maturity level, and benchmarking indicators to monitor this progress.

- The ability to conduct meaningful benchmarking across sites and geographical areas, with an assessment tool that has all the features of a reliable metric.

- An expert assessment of both the capabilities and culture underpinning your organisation’s risk management programme carried out efficiently with your resources and personnel.

Our Approach

We structure our Organisational Process Safety (OPS) service around Risk-Based Process Safety (RBPS), a continuous improvement method that involves a cycle of assessment, implementation and monitoring. Our OPS tool specifically addresses an organisation’s capabilities and culture. Its methodology goes a step further to minimise subjectivity by being:

- Scalable: Effective for any industry, for single or multiple facilities and for one or more workstream components

- Practical: Conducted mainly with workers in the workplace

- Precise, repeatable and reproducible: Accurate, consistent results across sites and assessment teams

Our targeted assessment tool measures and evaluates with precision an organisation’s maturity in terms of managing process safety risk to show whether your site has an avoidance, compliance or values-driven culture. The assessment results are derived from a combination of cultural elements and capabilities and show exactly where your organisation stands regarding the maturity level of risk management: From viewing safety as a hinderance to managing risk with an established, robust system within a healthy safety culture that is sensitive to future changes. Based on these results our specialists provide practical recommendations to help you reach your safety goals.

True to our values and role as trusted advisors, we listen carefully to our clients to ensure that our approach is adapted to their needs. A general outline of the process follows:

- Discussion: Together we meet to determine the scope of the service, identifying which areas of the organisation are under analysis and which workstreams are to be assessed.

- Targeted assessment: Specialists familiar with your technology perform assessments that determine the PS maturity level within each identified workstream; each receives a benchmark score for future monitoring.

- Prioritisation and recommendations: Assessment results are prioritised so that weaker areas are addressed more urgently than relatively strong ones; interventions are proposed that promote maturity progress.

- Implementation support (optional): Specialists are available on request at this stage to assist with the implementation of interventions.

- Reassessment: Within 5 years, an organisation can request a follow-up assessment to measure progress and redirect efforts

Why DEKRA?

- We are experts in both the technical and organisational factors that impact safety.

- We have impeccable credentials as a trusted partner to a cross-section of industries.

- We specialise in process safety innovations, such as our Organisational Process Safety tool.

- Focus Article: A New Approach to Process Safety Management

- Whitepaper: Do We Need to Re-Define Process Safety?

- Whitepaper: Managing Process Safety in Supplier Networks

- Whitepaper: Process Safety Excellence in Mergers and Aquisitions Beyond Technical Due Diligence

- Whitepaper: The Impact of Plastic Waste Reduction on Process Safety

- Implementing an Organisational Process Safety Assessment

- Whitepaper: Incident Investigation (Part 3): Improving Process Safety Maturity in Your Organisation